Volkswagen Factory, Kassel

WHERE COULD IT BE IMPORTANT, THAT EVERYTHING ENGAGES?

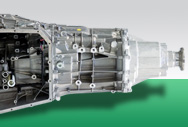

VIPA can identify with the production of gear transmission particularly well, of course. In the car these components handle several hundred Newton meters with surgical accuracy. In the Volkswagen factory in Kassel we made sure that performance and precision complement each other perfectly. Together with ThyssenKrupp VIPA installed the assembly line for double clutch transmission.

A project, where it was a question of going up a gear.

An order from the market leader to be carried out in the corporation’s most important transmission factory with the stipulation to increase the output – here the smallest error works like sand rather than transmission oil. VIPA accepted the challenges and the project team changed up a few gears. So a powerful network was created out of 37 SPEED7 CPUs, which synchronizes 14 robot stations, checks the quality in real-time and transmits all data to the digital control system. The result: Every two minutes one of these innovative switch boxes leaves the assembly line.

Likewise without friction losses: Cooperation of the partners.

This project shows once again how well VIPA works with other suppliers – and the result also convinced the designer of the assembly line:

The enormous performance, the large memory size as well as the integrated Ethernet communication processors of the VIPA SPEED7 CPUs has convinced us to equip our plants with VIPA systems also in the future

Bernfried Trittin,Project leader in charge ThyssenKrupp Krause GmbH